Digitalization and the rise of rapid manufacturing technologies have unlocked unprecedented potential to transform industrial supply chains. In theory, speed, flexibility, and global collaboration should already be the standard.

In reality, many supply chains are still built on outdated assumptions.

Protectionism, closed networks, and vendor lock‑in still dominate many supply chain strategies. Instead of embracing the power of collaboration, companies are left with rigidity, long lead times, and fragile dependencies—conditions that undermine resilience rather than protect it.

But if you ask us, that world should no longer exist.

Hiding the value chain is no longer protection.

It’s a liability.

The companies that win are not the ones that lock everything down. They are the ones that can see clearly, act quickly, and scale with confidence.

Why Protectionism Fails in a Disrupted World

Protectionist models rely on exclusivity and limited visibility. While they may feel safe in stable conditions, they quickly fail under pressure:

- Single‑source dependencies reduce flexibility

- Closed networks restrict scalability

- Poor visibility delays response when issues arise

Transparency flips this equation. It enables redundancy, informed decision‑making, and rapid adaptation. When companies understand their supply network in real time, they can intervene early—before disruptions turn into delays, and before inventory turns into capital locked on shelves.

Transparency Is No Longer a Risk—It’s a Competitive Edge

Transparency across the value chain has long been viewed with suspicion in industrial manufacturing. Many still associate it with loss of control, exposure of sensitive information, or compromised intellectual property.

But transparency—done right—is the opposite.

When implemented with structure, governance, rights‑based security, and fair compensation, transparency becomes a powerful enabler of speed, resilience, and trust. It gives companies clear insight into who produces their parts, under which standards, and with which capabilities—without sacrificing control over access, IP, or production rights.

- This balance is critical.

- Transparency without governance creates chaos.

- Governance without transparency creates inertia.

True competitive advantage lives in the space between the two.

Speed Built on Clarity—Proven at Scale

In modern supply chains, speed is not a “nice to have.” It is a prerequisite.

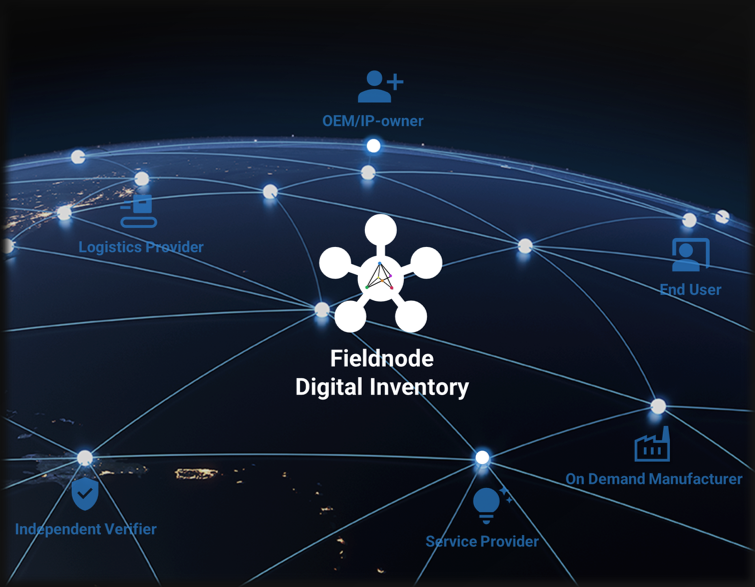

Through Fieldnode Digital Inventory, customers consistently experience inquiry to quote cycles of less than four days and manufacturing lead times below ten days. These are not best-case scenarios or aspirational targets. They are proven averages, validated across hundreds of real quotation requests in live industrial operations.

This level of performance is not achieved by pushing suppliers harder or compromising on quality. It is the outcome of an innovative platform based on structured transparency and standardized end‑to‑end digital workflows, bringing together End‑Users, OEMs, On‑Demand Manufacturers, and Service Providers into a single, integrated ecosystem. When these aspects align, speed is no longer a risk but rather the natural result of collective effort.

Escaping Without Losing Control‑In

Lock‑in models may promise simplicity, but they come at a cost: long‑term dependency and limited ability to adapt. A better approach combines controlled transparency with clear governance—where IP owners define how their designs are used, manufacturing partners remain audited and traceable, access is scoped, rights are enforced, and industry standards are non‑negotiable.

This principle is at the heart of our solution. . Each part can be easily sent for quotation, along with a digital journal, Statement of Work, and standards-based Inspection and Test Plan, enabling traceability, quote price accuracy, faster re-orders, and delivery reliability. Live updates, and integrated change management ensure that transparency extends throughout production—not just purchasing.

The result is a scalable, on-demand supply chain that replaces dependency and stockpiling with confidence and control.

The outcome isn’t disorder—it’s freedom. Freedom to scale.

Building Resilient, On-Demand Supply Chains‑Demand Supply Chains

By uniting speed, controlled transparency, and digital standardization, industrial companies can:

- Increase delivery reliability

- Reduce dependency on single suppliers

- Replace stockpiles with on-demand capacity‑demand capacity

- Respond faster to market changes

And this applies across industries and use cases—from spare parts to serial production, from legacy components to new designs.

The future of industrial manufacturing will not belong to those who hide their value chains behind walls. It will belong to those who can see clearly, move decisively, and govern intelligently.

It is the foundation of resilient, scalable, and competitive supply chains.

And it is what separates leaders from followers in the next era of industrial manufacturing.

Stefan Jansson

Commercial Director